Saamayntaxudunta atomizing dhoobada microporoussigaar elektaroonik ah

1. Porosity vs. xoogga

Iska horimaadka ugu horreeya ee ceramics: hoos u dhigista xoogga waxay keeni doontaa dhoobada inay hoos u dhigto budada, dhammaadka dayrta, ururku wuxuu u nugul yahay kala-goynta, taasoo keentay hoos u dhaca dhalidda.

2. Cabbirka daloolka vs. socodka saliidda

Cabbirka daloolkaceramics microporouswaa mid aan sinnayn qaab-dhismeed yar oo aan lahayn joomatari joogto ah.Cabbirka daloolku waa weyn ama yar yahay.Aperture ee ceramics microporous guud ahaan waxaa loola jeedaa qaybinta bareeg ah, in channel socodka joogtada ah, daloolin ugu yar ee caddadka saliidda door go'aan ka ciyaara, cadadka saliidda waa u dhiganta labajibbaaran ee daloolka, ka weyn ee aperture ah, si dhakhso ah saliidda.

3. Aperture vs. texture

Marka lagu daro saameyn ku yeelashada heerka hagida saliidda, daloolku waa tilmaame kale oo muhiim ah waa dhadhanka.Marka atomization-ka, haddii saliidda qiiqa waa qayb ka weyn atomized, socodka uumiga sameeyay waa yara qallafsan yahay, iyo dhibcaha uu sameeyay uumi ka dib way ka weyn yihiin, kaas oo leh xoogaa xoog leh oo dhadhan xiiso leh.Daloolka yar, ayaa si fiican u qulqulaya qulqulka uumiga ee ay sameeyeen dhibcaha saliidda atomization, sida ugu fiican ee qaybaha aerosol-ka ay sameeyeen, ayaa si fiican u saameynaya firidhsanaanta, lebis badan, dhadhan jilicsan.Sidaa darteed, inta yar ee hagaha hagaha saliida, ayaa ka sii fiican.

Falanqaynta dhibcaha xanuunka eexudunta atomizing dhoobada microporous

Hantida shidaalka iyo xoogga ceramics laguma xisaabin karo, sidaas darteed dalool ballaaran ayaa loo baahan yahay si loo helo awood ku filan oo saliid ah.Daloolin weyn ayaa ka dhigi doona daloolka dhoobada hoos u dhaca;Dhadhanka wanaagsan ee atomizing core wuxuu u baahan yahay dalool yar oo ku filan;Xoogga dhoobada, xakamaynta saliidda, shuruudaha dhadhanka ee daloolka ayaa si sax ah uga soo horjeeda.Ceramics ee saddexdan dhinac ee waxqabadka ma siin karaan fiiro gaar ah labadaba, waa khilaaf.Laakiin xudunta udubdhexaadka dhoobada dhoobada, oo ay ku jiraan tartanka asaasiga ah ee sigaarka elektaroonigga ah waa dhadhanka, taas oo ah waxqabadka u baahan in la dammaanad qaado marka hore.Sidaa darteed, cabbirka daloolka ayaa ku filan inuu keeno saliid ku filan.

1. Cabbirka daloolka dhuuban iyo borosity sare:

Tiknoolajiyada diyaarinta walxaha dhoobada Nano, xakamaynta xajmiga walxaha iyo xoojinta budada dhoobada, hel qaab dhismeedka daloolada ganaaxa iyo qaybinta cabbirka daloolka xoogga leh, iska ilaali khasaaraha xoogga ah ee ay sababto daloolada waaweyn.Kordhi isku-dhafka kala firdhisan ee budada dhoobada, kordhi qiyaasta dalool-samaynta, oo gaadh borosity sare

2. Iftiinkaceramics microporous:

Beddel qaabka walxaha, wanaaji xoogga gudaha ee walxaha dhoobada yar yar, si sax ah u qaabeeya oo u xakamee heerkulka sintering, si aad u hesho shahaadada sintering wanaagsan, si loo gaaro dheelitirka u dhexeeya porosity iyo xoogga.Naqshadaynta saxda ah ee warshadaha waxay gaari doontaa dheelitirka u dhexeeya xoogga, porosity iyo aperture, si loo gaaro habka saliidda ee ugu habboon iyo saameynta dhadhanka.

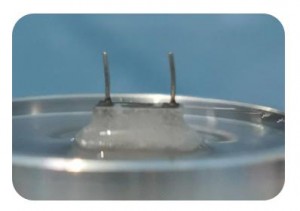

3. Dhibic kale oo xanuunka ah ee xudunta dhoobada ayaa ah uumiga nikotiinka iyo nuxurka saliidda sigaarka.Waxay u baahan tahay jawi heerkul deggan, iyo qaybinta heerkulku waa mid aan sinnayn.Si loo raadiyo dhadhanka ugu dambeeya, kuleyliyaha siliga ayaa loo baahan yahay si loo habeeyo si fiican oo wax loogu beddelo, markaa isbeddelka horumarka hadda jira ee xudunta atomization dhoobada waa in la sameeyo bir-is-habeyn lagu sameeyo substrate-ka dhoobada.Waxaa jira siyaabo badan oo loo bireeyo meelaha dhoobada ah, mid ka mid ah tignoolajiyada ugu caansan ee hadda lagu isticmaalo sigaarka elektaroonigga ah waa daabacaadda filimada qaro weyn, oo la mid ah koollada buraashka PCB.Nidaamkan kaliya laguma hirgelin sagxadaha fidsan, laakiin sidoo kale dusha 3D.

Waqtiga boostada: Jul-19-2022